Strainer

Questions

- Q Is there a standard for the mesh size of a strainer?

- Q What is pressure loss of the strainer?

- Q We would like to order screens and gaskets for our strainer, but we cannot find the model name.

- Q What is difference between SY-17 and SY-37?

- Q Which variations of strainer mesh sizes are available?

- Q When replacing the screen, should the gasket also be replaced?

- Q Can Y-type / Straight type strainer be used in the flow direction from bottom to top?

- Q SW-10's screen case on the side which flow is not applied to also has the fluid in it. Is the strainer out of order?

- Q Can U-type strainers (basket strainers) be used for steam or gas application?

- Q Do you have a pressure loss chart for each mesh size?

- Q Which models of strainer have the same screen in common?

- Q What is the difference between a perforation and a mesh?

- Q Please explain the reverse washing method for Y-type strainers.

- Q How should we select a proper strainer?

- Q Please explain horizontal piping for Y-type strainer on steam line.

- Q How can we know when to clean the screen?

- Q Are there any measures when differential pressure before and after the strainer is large or when fluid viscosity is large?

- Q Is it possible to use the paint of other than Yoshitake standard?

- Q Is it possible to produce strainers with a designated face-to-face dimension or strainers with a hinged cover?

- Q What are the features of different types of strainer?

QIs there a standard for the mesh size of a strainer?

Followings are standards mentioned by public organizations in Japan.

1. Construction standard specifications (for the construction of machinery and equipment), issued by Public Buildings Association

* 40mesh or more for water (80mesh or more when installed before a solenoid valve), 80mesh or more for steam

2. The common specifications for the construction of public housing, issued by the housing bureau, Ministry of Land, Infrastructure and Transport

* When a strainer is installed before solenoid valve, motor valve and a self actuated valve, the mesh size should be 80 or more.

QWhat is pressure loss of the strainer?

QWe would like to order screens and gaskets for our strainer, but we cannot find the model name.

Please check the shape (Y or U type), connection, face-to-face dimensions and body material of the strainer and contact us.

QWhat is difference between SY-17 and SY-37?

Please select depending on the mesh size: SY-37 for 120mesh or finer.

QWhich variations of strainer mesh sizes are available?

20 to 100 mesh are available (120 to 200mesh for SY-37 and SY-38). Please contact us for screens with perforation only. Refer to the list of screen.

QWhen replacing the screen, should the gasket also be replaced?

Please replace with the new gasket to prevent external leakage.

QCan Y-type / Straight type strainer be used in the flow direction from bottom to top?

Yes, but please install a blow valve to drain scale accumulating on the bottom of the rizer pipe.

QSW-10's screen case on the side which flow is not applied to also has the fluid in it. Is the strainer out of order?

No, the model has allowable leakage.

QCan U-type strainers (basket strainers) be used for steam or gas application?

U-type strainers are for liquid. For gas (including steam), Y-type strainers are recommended.

QDo you have a pressure loss chart for each mesh size?

Available only for the standard mesh of each model.

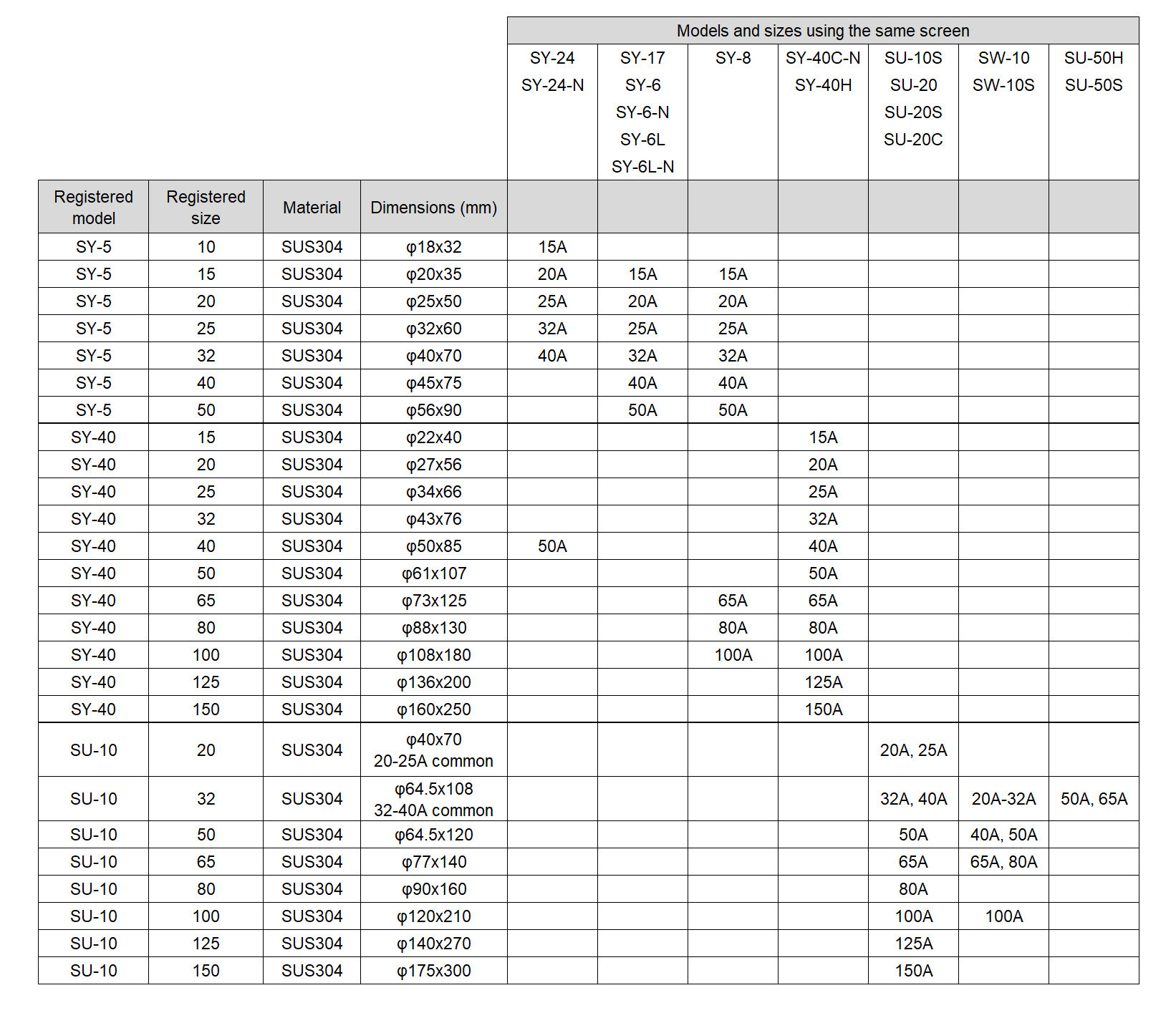

QWhich models of strainer have the same screen in common?

Please refer to the table.

Strainer shared screen reference table

Strainer shared screen reference table

QWhat is the difference between a perforation and a mesh?

"Perforation" refers to holes on the outer metal sheet of the screen and indicated by the hole size and the pitch.

"Mesh" refers to the wire mesh inside the screen and indicated by the mesh size. Mesh size is a unit to show how fine the mesh is. It shows the number of openings per inch (25.4mm).

[Example: if there are 20 openings, the mesh is referred to as 20 mesh.]

QPlease explain the reverse washing method for Y-type strainers.

Reverse washing is to wash a strainer by flowing fluid in the reverse direction in order to remove scales.?Install a bypass pipe and a blow valve around the strainer. The reverse washing should be applied only to single-layered screens. If this is applied to a double screen (perforated metal + mesh) the internal mesh may be torn off from the screen and damaged.

QHow should we select a proper strainer?

Select a strainer with the same size as the nominal size of piping. According to fluid type, select Y-type, U-type, straight type strainer.

If there is few space downward of the strainer for water, we recommend ST-10 since cleaning or replacement of screen (mesh) can be performed without tools.

QPlease explain horizontal piping for Y-type strainer on steam line.

Horizontal piping is necessary on steam line to prevent condensate retention or freezing.

QHow can we know when to clean the screen?

Install pressure gauges before and after the strainer and use the strainer within 0.1 MPa of differential pressure. When differential pressure approaches to 0.1 MPa, clean the screen (mesh).

QAre there any measures when differential pressure before and after the strainer is large or when fluid viscosity is large?

Reinforcement of the screen or replacement with different type of screen can be measures. Please contact us.

QIs it possible to use the paint of other than Yoshitake standard?

Please contact us with the Munsell color number. We will review and reply.

QIs it possible to produce strainers with a designated face-to-face dimension or strainers with a hinged cover?

It is possible for steel type strainer such as SY-13 or SU-6.

QWhat are the features of different types of strainer?

Y-type strainer: compact type with low fluid resistance and small installation space

U-type strainer: bucket-shaped screen with a handle, having a larger filtration area than Y-type

W-type strainer: duplex type whose flow path can be switched and screen can be cleaned without stopping the flow

Temporary strainer: for pipe flushing before starting operation