Notes for Piping Installation

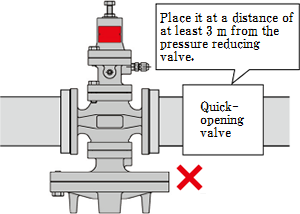

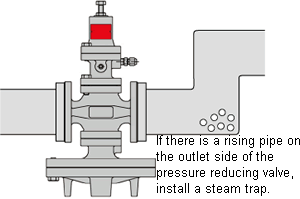

Most of the troubles of the pressure reducing valve are caused by foreign substances or condensate disturbance inside the piping.

The trouble caused by foreign substances or condensate disturbances (rust generated by condensate retention and troubles by water hammer) is subject to a charge during the warranty period.

Make sure to read the instruction manual delivered together with the product before piping work.

Notes for Piping Installation

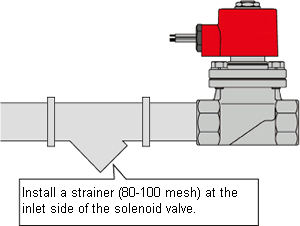

- Make sure to install a strainer so that foreign substance inside the piping can not enter valves.

- Install the bypass line for pressure reducing valves, temperature regulating valves, trap, etc.

- Seize a designated point with a wrench when installing.

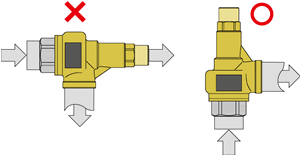

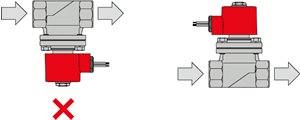

- Install the product so that the fluid flowing and the arrow marked on the product are in the same direction.

- Support the piping so that excessive load is not applied to the valves.

If you ask for repairing and presence at operation, please contact our local distributors for details.

Please see below for each product.